Hardwood Styles

The number of hardwood choices, patterns, colors, textures and price points can intimidate even the most experienced shopper. Knowing the basic styles can provide you with a firm foundation upon which to begin your hardwood-shopping journey. Choosing your ideal hardwood style is all about knowing the right combination of aesthetics, performance, and budget that meets the needs of your lifestyle.

Personal Style

- Designs: medallions, running on the diagonal, or creating borders

Types

1. Pre-finished:

- Ready for installation

- Boards already sanded, stained and finished

- Harder, better - protected surface

- Wider variety of wood species

- Save hours of labor and cleanup

- Extended finish warranty

2. Unfinished:

- Allow you to have a custom job

- You choose the wood species

- It’s sanded and stained on site

- Can level the surface after installation

- No extended finish warranty

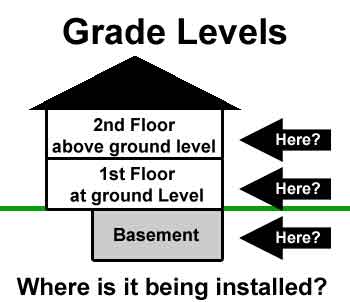

Location

- Look at installation site for location limitations

- Solid floors - susceptible to moisture, not recommended for basements, or concrete slabs

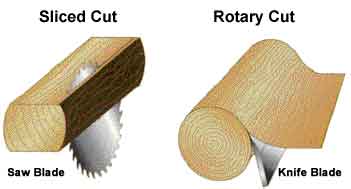

Grain and cut

- Styles are the result of the species available

- Species: red oak, white oak, maple, cherry, white ash, hickory or pecan

- Each species has unique graining and texture

- Graining on the boards determined by the way it has been cut

- Two cutting processes. “Sliced Cut” -more uniform pattern and “Rotary Cut” - displays a larger and bolder graining pattern

Color

- Each species gives choices of color and finishes

- Choose coordinating or contrasting with cabinetry and furniture

- Darker woods- more formal

- Natural colors- more casual

Finish

- Different types for pre-finished or job site finished

- Lower gloss levels - better for active rooms

- Lower gloss or matte finishes minimize dirt and scratches

- High gloss finish for formal décor

Upkeep

- No more waxing and scrubbing

- Pre-finished - hard, durable, urethane-based finishes

- Chips of Aluminum Oxide added to increases the urethane finish’s life

Floor protection

- Factory finished: several coats applied to the surface

- Many companies apply 6-10 coats of an ultra-violet (UV) cured urethane

- UV cured urethane: difficult to duplicate on a job site finish

- Factory finishes - more consistent and durable

- Do not wash your floor with a mop

- Water is not a friend of hardwood

- Floors won't watermark like old waxed floors

- UV cured finishes do make floors easier to maintain than waxed floors

Pre-finished choices:

- UV-cured – factory finishes cured with Ultra Violet lights versus heat

- Polyurethane – clear, tough and durable applied as a wear layer

- Acrylic-urethane – different makeup than Polyurethane, same benefits

- Ceramic – advanced technology allowing ceramics to increase wear layer resistance

- Aluminum oxide – added to urethane finish for increased abrasion resistance

- Acrylic impregnated – acrylic monomers injected into cell structure for hardness, then finished with a wear layer

Job-site hardwood flooring

- Start with a bare (unfinished) floor, then sand, stain, and finish

- If the subfloor is acceptable you can have a custom stained

- Can have a floor to match existing trim

- Advantage: smoother floor between planks

- Process is messy and takes several days

Methods:

- Water Based Urethane – water used as part of the makeup of the finish

- Solvent Based Urethane – oil used as part of the makeup of the finish

- Moisture Cured Urethane – similar makeup as solvent-based urethanes, finish needs moisture to cure

Board widths

- Boards come in various sizes

- Narrower board widths called “strips”

- Wider boards called “planks”

- Board width visually impacts a room

- Narrow boards expand a room

- Wider boards work well in a larger room

Edge knowledge

- Floors come in either a beveled edge or a square edge

- Each edge creates a specific look and feel

Edge types:

- Square edge: edges all meet squarely for a uniform, smooth surface (contemporary and formal)

- Eased edge: boards slightly beveled to length and/or the end joints, hides irregularities, plank heights, also called micro-beveled edge

- Beveled edge: distinctive groove, informal and country décor, beveled edges sealed completely, dirt easy to sweep or vacuum out of the grooves

Species Guide

Hardness – Janka hardness test

- measures the force needed to embed a .444 inch steel ball to half its diameter in a piece of wood

- higher the number the harder the wood

- one of the best methods to measure the ability of wood species to withstand indentations

- general guide when comparing various species

- construction and finish also important in the durability and ease of maintenance

HARDNESS RATING

- Douglas Fir 660

- Southern Yellow Pine (shortleaf) 690

- Southern Yellow Pine (longleaf) 870

- Black Cherry 950

- Teak 1000

- Black Walnut 1010

- Heart Pine 1225

- Yellow Birch 1260

- Red Oak(Northern) 1290

- American Beech 1300

- Ash 1320

- White Oak 1360

- Australian Cypress 1375

- Hard maple 1450

- Wenge 1620

- African Pedauk 1725

- Hickory 1820

- Pecan 1820

- Purpleheart 1860

- Jarrah 1910

- Merbau 1925

- Santos Mahogany 2200

- Mesquite 2345

- Brazilian Cherry 2350

Red Oak

Red Oak is the most abundant growing species in the United States. The sapwood of Red Oak is white to light brown while the heartwood has a pinkish reddish brown tone. It comes in four different grades:

Quartersawn

highest quality with almost no knotholes or color deviation.

Smooth Finish suggested.

Select

Second highest quality with few knotholes and very slight color deviations. Smooth finish suggested.

#1 Common

Third highest quality with more pronounced knotholes and color

deviations. Suggest hand scraped or smooth.

#2 Common

Lowest quality with many knotholes and color deviations. Suggest hand scrape only.

White Oak

White Oak is similar to Red Oak but is slightly more dense and has longer rays. The sapwood is light colored and the heartwood is light to dark brown. White Oak comes in the same four grades as Red Oak:

Quartersawn

highest quality with almost no knotholes or color deviation.

Smooth Finish suggested.

Select

Second highest quality with few knotholes and very slight color deviations. Smooth finish suggested.

#1 Common

Third highest quality with more pronounced knotholes and color

deviations. Suggest hand scraped or smooth.

#2 Common

Lowest quality with many knotholes and color deviations. Suggest hand scrape only.

Cherry

American Cherry grows primarily in the Midwestern and Eastern United States and is very hard and dense. The sapwood varies from a rich red to reddish brown and will darken with age. The sapwood tends to be a creamy white.

Hickory/Pecan

Hickory is the hardest, heaviest, and strongest American wood. The sapwood of hickory is white and the heartwood is pale to reddish brown. It can be finished smooth or hand scraped.

Maple

Growing in the Pacific Northwest, maple tends to be light but a very dense wood. Generally there is no marked difference between the sapwood and heartwood. Because of its density, maple is not recommended for high humidity areas. Smooth Finish suggested.

Pine

Tends to be a soft wood that absorbs moisture very well and is recommended for high humidity areas. The sapwood in pine is usually light yellowish-white while the heartwood tends to be yellowish-orange. Can be finished smooth or hand scraped.

Reclaimed Pine

Same characteristics as Pine, however it is recycled from old buildings (usually barns).

Walnut

Walnut grows primarily in the Eastern United states. The sapwood tends to be white while the heartwood ranges from a deep chocolate to purplish black. Walnut is great for borders and is finished smooth.

Mesquite

Mesquite grows primarily in the Southern United states and is known for being a very hard and durable wood. The sapwood tends to be pale while the heartwood is reddish brown. Mesquite usually contains lots of knotholes and a smooth finish is recommended.